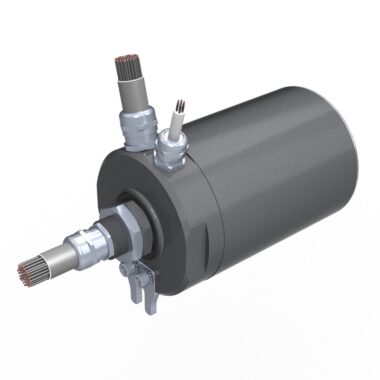

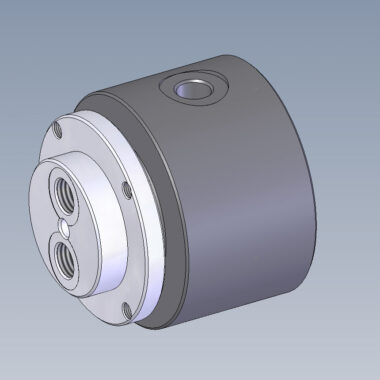

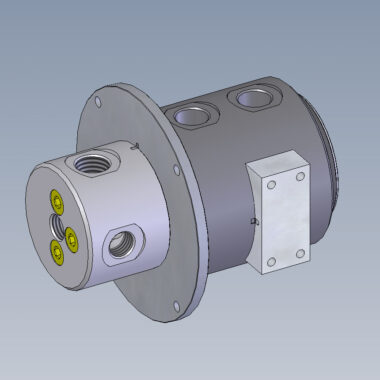

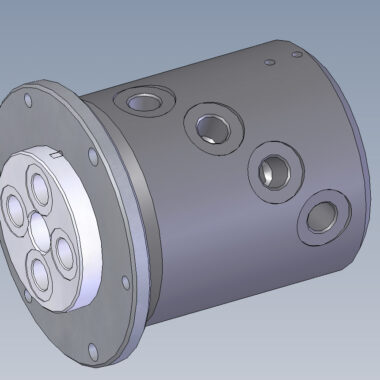

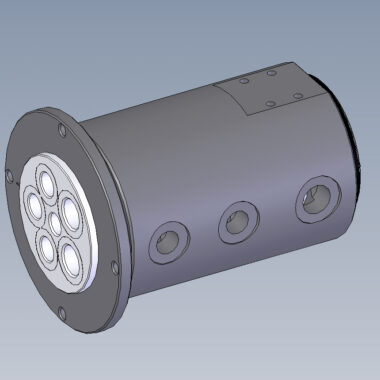

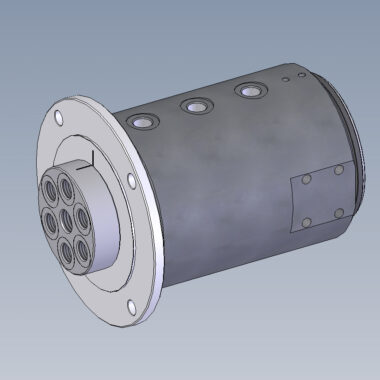

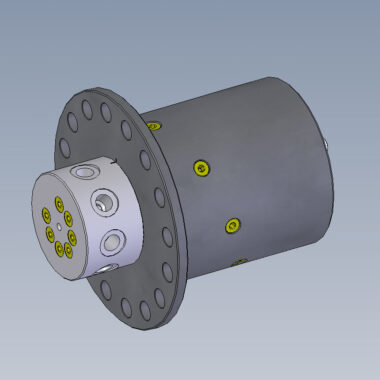

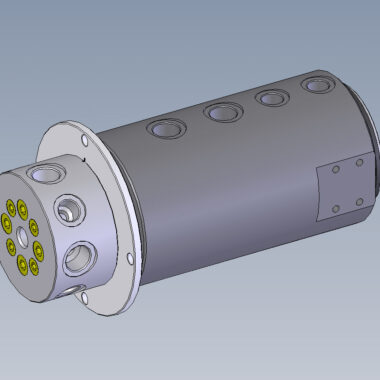

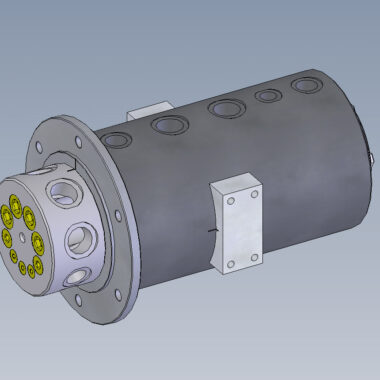

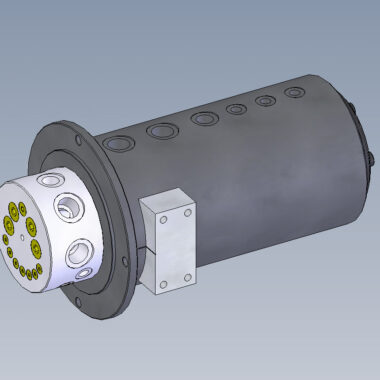

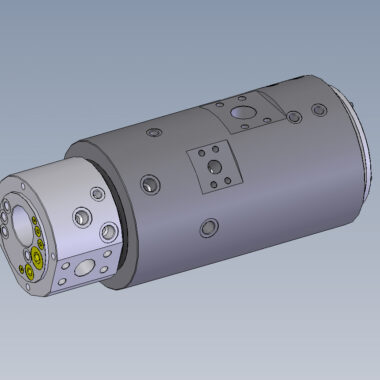

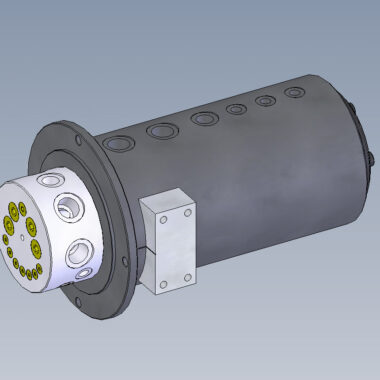

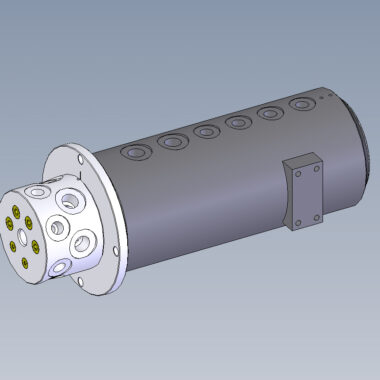

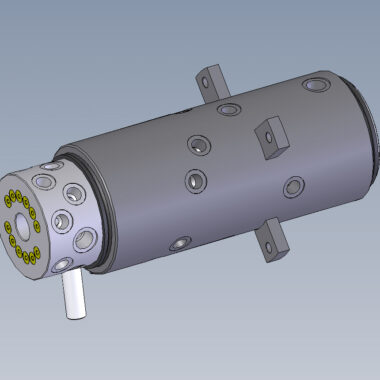

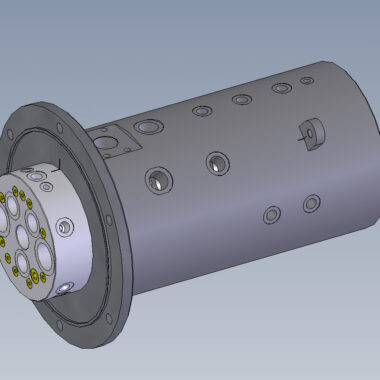

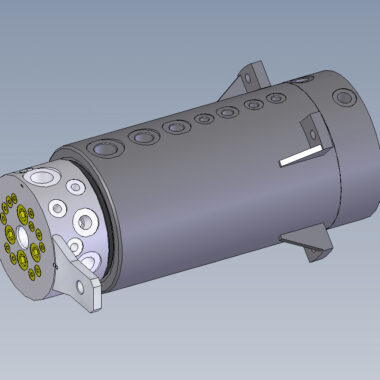

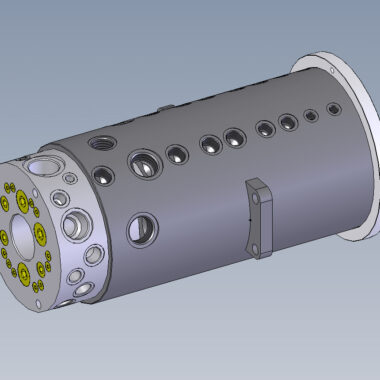

Rotary joints are devices used in hydraulic and pneumatic systems to direct fluid flow to different directions or circuits. These distributors consist of a cylindrical body with internal channels and a rotating section that can be positioned in various positions to connect the fluid flow to different points in the system.

They are commonly used in a wide range of applications, including:

- Earth-moving machinery: In vehicles and earth-moving machinery, such as excavators and loaders, rotary distributors are used to control the flow of hydraulic fluid to the various actuators, such as cylinders and motors, that control the movement of the machine, such as lifting the boom or moving the blade.

- Industrial machinery: In industrial automation and production systems, rotary distributors are used to direct the flow of fluid to actuators that control various operations within the production process, such as the opening and closing of grippers, clamps and other equipment.

- Lifting and handling systems: In industrial lifting and handling systems, such as cranes and lifting platforms, rotary distributors are used to control the flow of fluid to hydraulic actuators that control the movement of the structure and the lifting of the load.

- Agricultural machinery: In agricultural machinery, such as tractors and harvesting machines, rotary distributors are used to control the flow of fluid to hydraulic actuators that control different functions of the machine, such as lift height and speed of movement.

- Aerospace and shipbuilding: In the aerospace and shipbuilding sectors, rotary distributors are used to control the flow of fluid to flight control systems, propulsion systems and other critical actuators.

Slip rings, also known as rotary electrical interfaces or rotary electrical connectors, are mechanical/electrical devices used to transfer electrical energy and signals between rotating and stationary parts of a machine or system. These devices enable the smooth transfer of electrical signals across a rotary interface.

Slip rings are mainly composed of two parts:

- Rotor: This is the part of the slip ring that rotates with the rotating component of the machine. The rotor is typically connected to the power supply and signals to be transmitted through the rotating interface.

- Stator: This is the fixed part of the sliding ring that remains in position while the rotor rotates around it. The stator is connected to the cables or circuits that receive the power and signals from the rotor and transfer them to the fixed part of the system.

Slip rings are used in a wide range of applications, including:

- Industrial machinery: In industrial machinery requiring continuous rotating movements, such as coil winders, automatic lathes and CNC machine tools, slip rings enable the transfer of control signals and electrical power between the rotating and fixed parts of the machinery.

- Transport applications: In transport systems that include rotating parts, such as tower cranes, forklifts, trains and rotating platforms, slip rings are used to transfer control signals and electrical power between the rotating and fixed parts of the system.

- Aerospace: In aerospace systems, such as scanning radar, satellite antennas and aircraft-mounted measuring instruments, slip rings are used to transmit signals and electrical power through rotating parts without interference.

- Marine applications: In marine and offshore systems, such as sea cranes, rotating radar and dynamic positioning systems on ships and offshore platforms, slip rings enable the reliable transfer of signals and electrical power through the rotating parts of the system.

In general, slip rings are essential components in many applications where the reliable transfer of electrical signals through rotating parts of a system is required. Their design varies according to the specifications of the application, including the power and signal transfer requirements and the required rotational speed.

Rotary joints